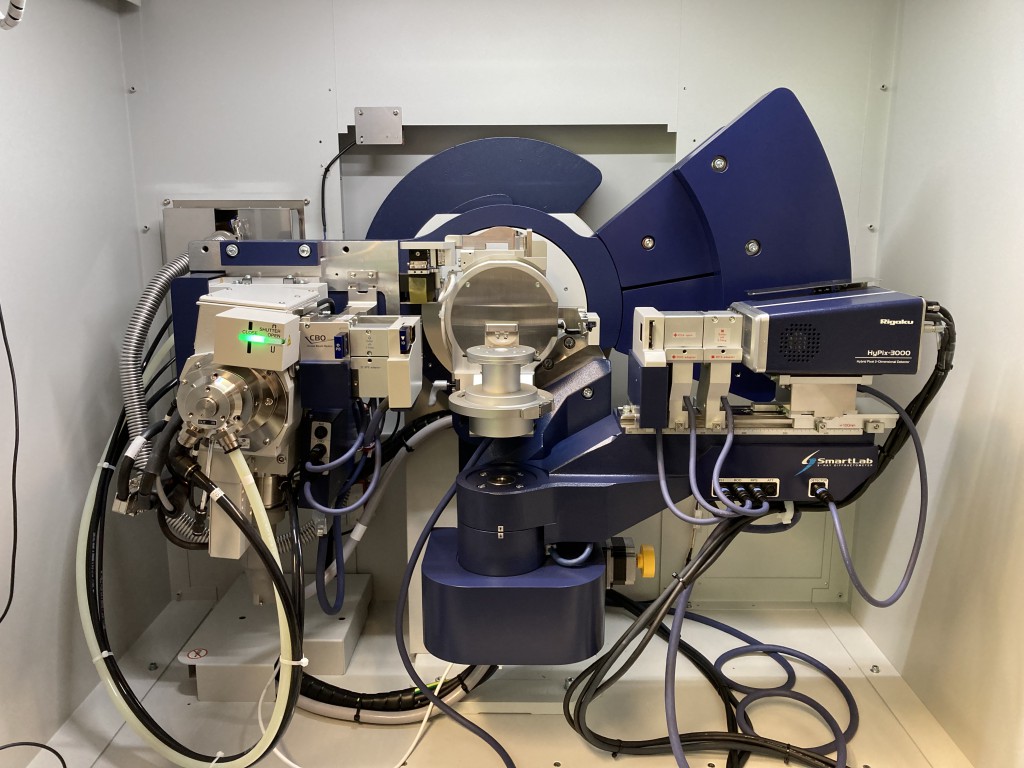

Instrument

Rigaku Smartlab High Resolution X-ray diffractometer (launch 2018; installed at NPPT in 5/2022)

Availability, Application and Scheduling, Costs

The instrument is available to users outside the Winterer group upon request. Advanced support is possible in a collaborative manner (including coauthorship). You may apply for measurement time by sending an e-mail to

In your e-mail you should shortly describe

- your samples (composition and other information available for example about phase or structure) including hazards,

- scientific goal of your experiment

- method of the Rigaku Smartlab you intend to use

We will then schedule your experiment.

The instrument is dedicated to academic use. Members of academic groups are encouraged to apply for measurement time and to use it for academic purposes. Users will be asked to participate fairly in costs for maintenance and consumables.

User Modes, Rules and Procedures, Acknowledgements

- one time user / few measurements per year: we will perform the measurement with you or in collaboration depending on the complexity of the experiment

- frequent user: after training by an expert user, one dedicated person per scientific group will be allowed to perform measurements her- / himself

- expert user is a trained NPPT group member. Only expert users are allowed to train other users.

Training Requirements for frequent users before independent operation of the instrument and other rules and procedures are described in the document (preliminary version):

If you publish or present data collected with NPPT’s Rigaku Smartlab High Resolution X-ray diffractometer, please acknowledge the funding and any non-collaborative support as:

The X-ray data were collected using the Rigaku Smartlab High Resolution X-ray diffractometerof the Nanoparticle Processing Technology (NPPT) group at the University Duisburg-Essen. The instrument is funded through the DFG (German Research Foundation) Instrument proposal INST 20876/395-1 FUGG and the state of North Rhine-Westfalia, Germany. We would like to thank N.N.* for the assistance in using the instrument.

* Please include the name of the supporting scientist.

Instrument details

Source

- 9 kW rotating anode X-ray generator using a Cu-Anode

Optics

- CBO optics for divergent and parallel beam operation

- CBO optics for spots size of ~ 100 µm: converts line to point focus while conserving high beam intensity

- Ge(220) and Ge(400) double monochromators for high angular resolution measurements

- Ge(220) and Ge(400) double analysator crystals

- collimators for beam shaping

Sample stages & measurement modes

- X-Y- and RxRy-sample stages

- theta-theta goniometer with in-plane goniometer arm

- multifunctional Euler cradle and rotation stage

- sample stage for micro-XRD (including mapping)

- sample changer with 10 positions including sample rotation

- different sample holders for powder samples including Si single crystals (zero background)

- components for SAXS, 2D-SAXS/WAXS, U-SAXS and GI-SAXS

- capillary spinner

Detectors

- Hypix-3000-2D detector for 0D-, 1D- and 2D mode measurements

- observation camera (including mapping)

DAQ, Analysis & Accessories

- control computer

- control and analysis software

- integrated crystallographic data base: COD & ICDD-PDF-2

- calibration samples

Science

Typical sample types and structural information obtainable are

- nanoscaled powders and solids (crystal-, microstructure, phase analysis, and texture)

- thin (polycrystalline and epitaxial) films (crystal-, microstructure, phase analysis, and texture),

- stress, thickness, roughness, and coherence

- colloidal nanoparticles (microstructure).

Methods and?measurement modes available:

- X-ray powder diffraction (XRD)

- microdiffraction, including mapping

- Small- and wide angle scattering in transmission (2D: SAXS, WAXS; 0D: SAXS, USAXS)

- Small- and wide angle scattering in grazing incidence (GISAXS, GIWAXS)

- Texture determination (pole figures, ODF)

- high resolutions diffraction

- stress determination

- reciprocal space map (RSM)

- high resolution rocking curves (HRRC)

- reflectometry (XRR)

Examples

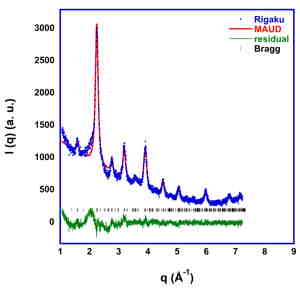

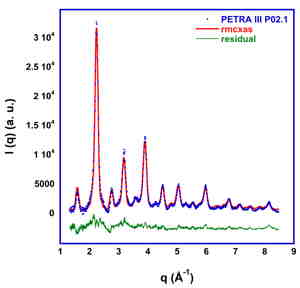

X-ray powder diffraction / WAXS

|  |

X-ray powder diffraction of CVS nano-LaFeO3 (15 min measurement time) with Rietveld refinement (left) and synchrotron PDF-data analyzed (background removed) by Reverse Monte Carlo simulation (right).

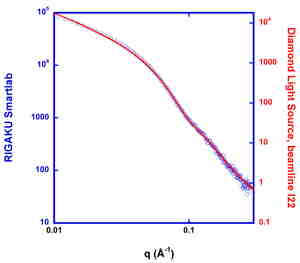

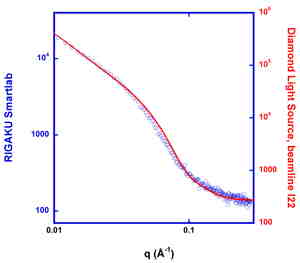

Small angle scattering (SAXS)

|  |

Comparison SAXS data of CVS nano-SnO2(rutile) in powder form (left) and as aqueous colloidal dispersion (right). Diamond Light Source, beamline I22, measurement time for powder 2 s, for colloidal dispersion 24s (red) and measurement time 10 min Rigaku Smartlab (blue).

Teaching

The instrument is used extensively for teaching in the NanoEngineering study program:

- NanoEngineering Labcourse (Bachelor)

- Nanocharacterization Labcourse (Bachelor)

- Bachelor projects and Bachelor thesis

- Nanocrystalline Materials Labcourse (Master)

- Master projects and thesis

Literature

Funding

The instrument is funded through the DFG (German Research Foundation) instrument proposal INST 20876/395-1 FUGG and the state of North Rhine-Westfalia, Germany.

Publications benefiting from this instrument

12. M. Abedini and S. Hanke, Microstructural and tribological properties of multilayered coatings developed through heat treatment on the surface of CP-Ti, Surface and Coatings Technology, 495 (2025), 131590; doi:10.1016/j.surfcoat.2024.131590

11. A. Eitner, A. K. Al-Kamal, M. Y. Ali, M. Y., M. A. Sheikh, C. Schulz, and H. Wiggers, Spray-flame synthesis of Nb-doped TiO2 nanoparticles and their electrochemical performance in sodium-ion batteries, Applications in Energy and Combustion Science 17 (2024), 100252; doi:10.1016/j.jaecs.2024.100252

10. Y. Gao, G. Yin, Y. Li, T. Köhler, I. Kardosh, and M. Schmid, An Efficient S and Se Co-Annealing Strategy for Performance Enhancement of Solution-Processed Submicron CuIn (S, Se) 2 Solar Cells, IEEE Journal of Photovoltaics 14 (2024) 246; doi:10.1109/JPHOTOV.2023.3334479

9. M. Schmid, M. Ketharan, J. Lucaen, and I. Kardosh, Sequentially PVD-Grown Indium and Gallium Selenides Under Compositional and Layer Thickness Variation: Preparation, Structural and Optical Characterization, Advanced Materials Interfaces (2024) 2301086; doi:10.1002/admi.202301086

8. H. Schönrath, J. Wegner, M. Frey, M. A. Schroer, X. Jin, M. T. Prez Prado, R. Busch, and S. Kleszczynski, Novel titanium based sulfur-containing BMG for PBFLB/M, Prog. Addit. Manuf. 9 (2024) 601-612; doi:10.1007/s40964-024-00668-z

7. H. Schönrath, J. Wegner, M.A. Schroer, M. Frey, L- Bruckhaus, R. Busch, and S. Kleszczynski, Impact of processing parameters on mechanical properties of additively manufactured Ti-based BMGs, MATEC Web Conf. 406 (2024) 07003; doi:10.1051/matecconf/202440607003

6. L. Spee, J. Konietzka, A. Grundmann, N. Stracke, M A. Schroer, M. Winterer, H. Kalisch, M. Heuken, A. Vescan, G. Bacher, and F. Muckel, Photogating through Unidirectional Charge Carrier Funneling in Two-Dimensional Transition Metal Dichalcogenide/Perovskite Heterostructure Photodetectors, ACS Appl. Opt. Mater. 2 (2024) 852-861; doi:10.1021/acsaom.4c00113

5. J. Wegner, L. Bruckhaus, M. A. Schroer, M. Rayer, H. Schönrath and S. Kleszczynski, Zr-based bulk metallic glasses in PBF-LB/M: near-polished surface quality in the as-built state, Prog. Addit. Manuf. 9 (2024) 585-591. doi:10.1007/s40964-024-00667-0

4. T. E. Czerny, Q. Shen, J. Konieczny, M. A. Schroer, M. Winterer, and F. Muckel, Efficient Narrowband Photoconductivity of the Excitonic Resonance in Two-Dimensional Ruddlesden Popper Perovskites Due to Exciton Polarons, J. Phys. Chem. Lett. 14?(2023) 4850 ? 4857; doi:10.1021/acs.jpclett.3c00710.

3. Q. Fu, W. Li, and F.E. Kruis. Highly conductive copper films prepared by multilayer sintering of nanoparticles synthesized via arc discharge, Nanotechnology 34 (2023) 225601; doi:10.1088/1361-6528/acbd1f.

2. J. Geiss, J. Böker, J. Schulte, B. Peng, M. Muhler, and M. Winterer, LaCo1-xFexO3 Nanoparticles in Cyclohexen Oxidation, J. Phys. Chem C. 127 (2023) 5029-5038.; doi:10.1021/acs.jpcc.2c08644.

1. J. Kruip, I. Kardosh, T. Köhler, Y. Gao, and M. Schmid. Growth of (Ag,Cu)(In,Ga)Se2 Absorbers under Band Gap Variation and Characterization with a Focus on Optical Spectroscopy, Process 11 (2023) 392; doi:10.3390/pr11020392.